Granulation is the art of creating patterns in relief with miniscule beads (granules) of gold. Requiring extreme concentration and care, this technique—which dates back to the ancient era—has been one of the traditional skills mastered and perpetuated by Cartier workshops since 2013.

The art of granulation dates back to the third millennium BCE, but enjoyed its heyday in Etruria (now Tuscany) in the eighth century BCE. Probably learned from Near Eastern artisans, the technique was perfected by Etruscan goldsmiths. they created objects and jewelry with decorative patterns made up of hundreds, indeed sometimes thousands, of tiny spheres of gold of various sizes.

Interest in this demanding art was rekindled in the nineteenth century by the discovery of jewelry and other precious objects in tombs of Etruscan aristocrats. It took modern-era artisans several decades of patient research to recover the manual methods and techniques behind this ancient skill.

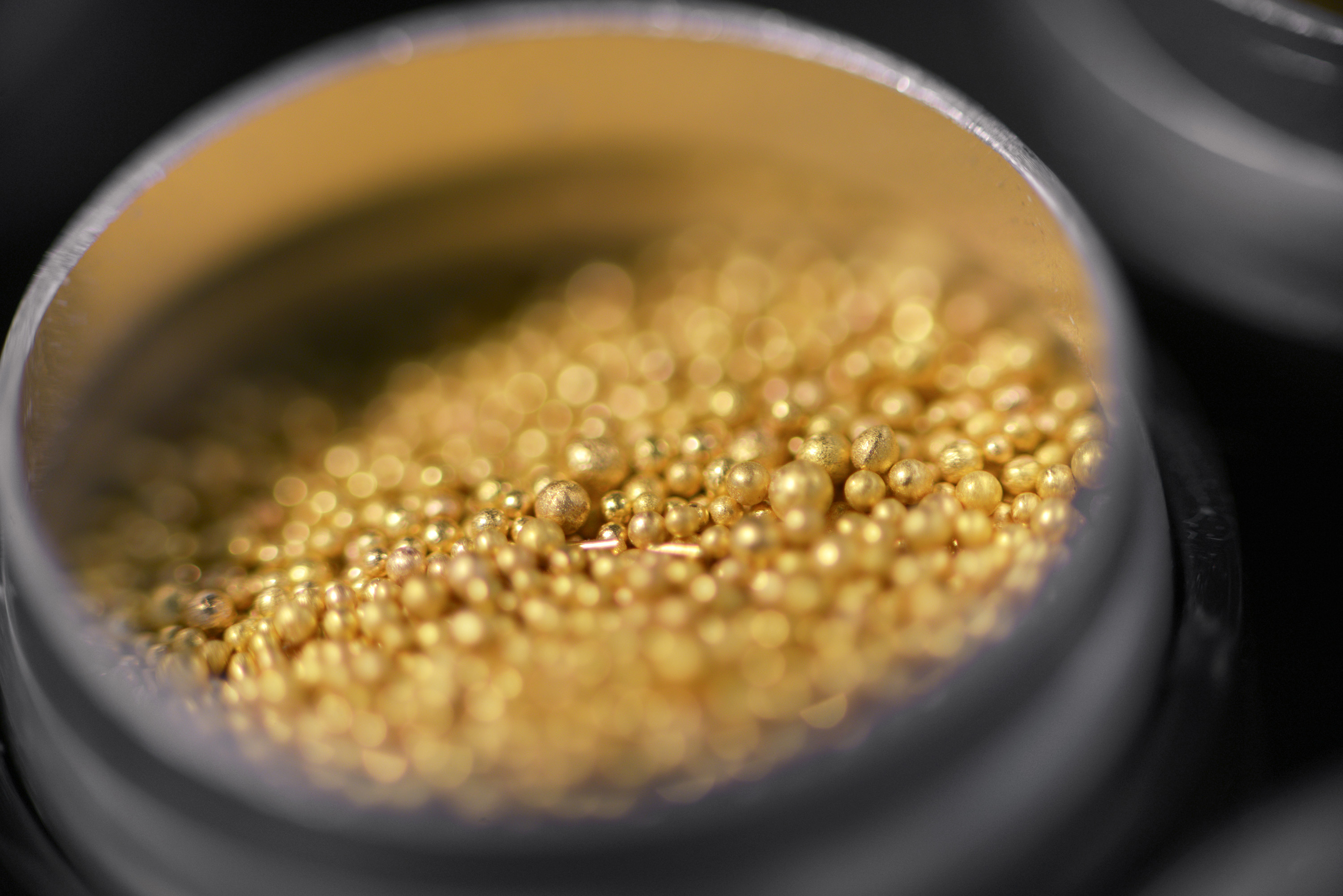

Cartier introduced this rare art into its workshops in the 2010s, directly seeking help from specialists at the Louvre Museum in order to perfect the technique. First, the granules are prepared by cutting gold wire whose diameter determines the size of the bead; granules of different sizes can be used to create variations in relief and effect.

Next, the beads are placed on a pattern incised by hand on the surface of, say, a watch dial, and are finally soldered at low temperature. That is the trickiest phase in the process, because the gold of the granules must fuse into the gold of the dial without melting or changing shape. Every time the blowtorch approaches the object, the work already accomplished is threatened, and the flame must be applied to a watch dial between two and three thousand times. Constant vigilance and great dexterity are thus required.

In 2013, the first watch with granulated dial depicting a panther emerged from the assembly of four thousand beads of gold and hundreds of hours of work. A watch with a granulated orchid design followed in 2015, while in 2016 a second panther watch employed enameling as well as granulation.

Since 2014 this skill has been incorporated into Cartier’s Maison des Métiers d’Art (House of Craftsmanship) in La Chaux-de-Fonds, Switzerland.